Specialized solutions for exceptional results

Unlocking excellence through innovative specialized processes

Our range of services

Explore our diverse range of specialized processes tailored to elevate your products

Electroplating

Electroplating

Enhancing surface properties with precision.

Electroless Plating

Electroless Plating

Achieving uniform and controlled coating thickness.

Anodization

Anodization

Providing corrosion resistance and aesthetic appeal.

Chemical Conversion Coating

Chemical Conversion Coating

Improving durability and surface quality.

Phosphating Coating

Phosphating Coating

Enhancing paint adhesion and corrosion resistance.

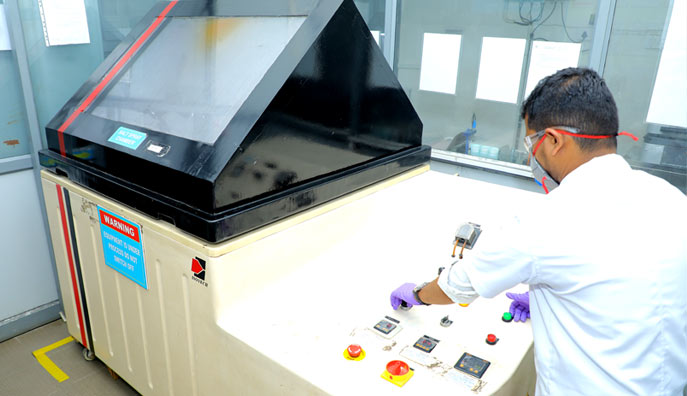

Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT)

Ensuring product integrity with advanced inspection.

Primer and Paint Application

Primer and Paint Application

Ensuring optimal surface preparation and finishing.

What sets us apart

Stringent quality control

With rigorous quality control measures in place, we guarantee the reliability, durability, and safety of every component processed.

Advanced technology

We invest in cutting-edge technology, including NADCAP-certified facilities and advanced machining equipment, to deliver superior results.

Tailored solutions

Our team customizes a range

of process to your exact specifications, ensuring optimal performance and adherence

to industry standards.

Specialized expertise

Leveraging decades of specialized expertise in the aerospace and automotive industries, we possess the know-how to handle intricate processes with precision.

Trusted partner

Join a roster of satisfied clients who trust us as their preferred partner for specialized processes, backed by our proven track record of excellence.

On-time delivery

Our commitment to punctuality means you can rely on us for timely delivery, minimizing downtime, and optimizing operational efficiency.

Our machines

-

Taber Abrasion Tester (ASTM D 4060)

-

Salt Spray Test Machine (ASTM B 117)

-

XRF Machine for Coating Thickness (ASTM B 568)

-

Water Immersion Test Equipment (AMS 2700)

Taber Abrasion Tester (ASTM D 4060)

Taber Abrasion Tester (ASTM D 4060)

Taber Abrasion Tester (ASTM D 4060)

Used for testing abrasion resistance of coatings.

Salt Spray Test Machine (ASTM B 117)

Salt Spray Test Machine (ASTM B 117)

Salt Spray Test Machine (ASTM B 117)

Utilized for evaluating the corrosion resistance of coatings

in a salt-laden environment.

XRF Machine for Coating Thickness (ASTM B 568)

XRF Machine for Coating Thickness (ASTM B 568)

XRF Machine for Coating Thickness (ASTM B 568)

Employed to measure the thickness of coatings

using X-ray fluorescence technology.

Water Immersion Test Equipment (AMS 2700)

Water Immersion Test Equipment (AMS 2700)

Water Immersion Test Equipment (AMS 2700)

Conducts tests to assess the resistance of coatings to water immersion.

Our processes

Electroplating

Electroplating

Applying metal coatings like zinc, nickel, and cadmium for enhanced durability and corrosion resistance.

Anodization

Anodization

Offering sulfuric acid anodization, hard anodization with dyes, and PTFE coatings for superior surface protection.

Conversion Coating

Conversion Coating

Providing chemical conversion, phosphating, black oxide coatings, and passivation treatments for improved surface properties.

Spray Painting

Spray Painting

Applying primer, high-gloss finishes, and abrasion-resistant coatings for aesthetic appeal and environmental protection.

Non-Destructive Testing

Non-Destructive Testing

Conducting fluorescent and magnetic particle inspections to detect surface defects and ensure component integrity.

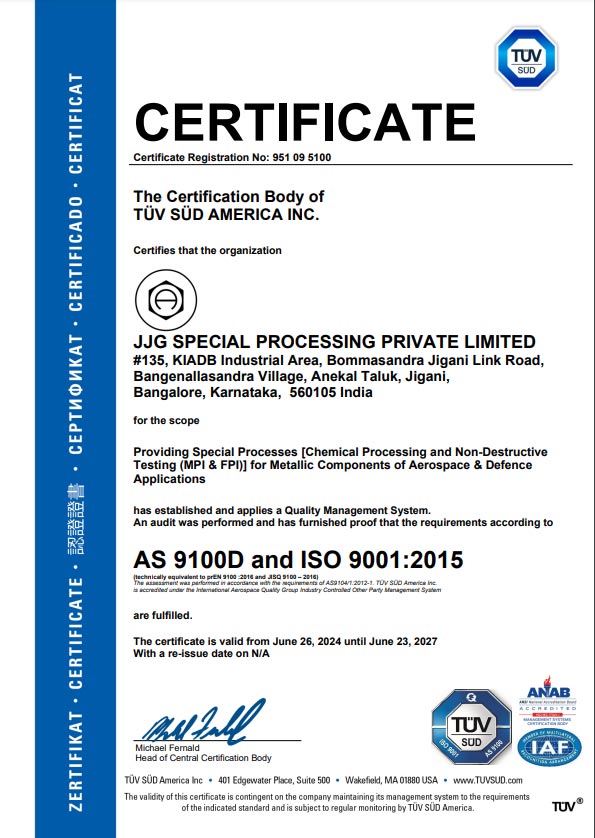

Assurance standards

- Compliance with the AC 7108/4 checklist

- NADCAP approved facility

- Water immersion test

- Salt spray test

- Copper sulfate test

- Coating weight test

- Adhesion test

- Taber wear test

- Coating thickness test

- Oxalic acid test

- Smut test

- Solution analysis

- Paint color and gloss testing

- Solvent resistance testing

- Adhesion tape testing

- Secure storage facilities for chemicals

- Adherence to safety protocols and regulations